Professional installation can guarantee the high-quality use of the products, we provide you with detailed installation tutorials to ensure that you can filter security risks, so that you can use more safely

This kind of cable has its own characteristics from construction difficulty, method and technology. Because the shell of this type of cable is drawn by a certain length of copper pipe, the length of cable and the number of wire cores are limited to a certain extent, which is shown in the following aspects: because the length of copper pipe is constant, the larger the wire core, the larger the outer diameter, and the forming of the cable core.

Install training service and enjoy professional training after registration

To help you learn more about the MI cables and to allow you to choose the right model on your own, we offer a resource download of the MI cable selection manual and specifications

DownloadMineral insulated cables provide a simple solution to many complex wiring problems and provide reliable and permanent installation for almost all types of circuits.

provides the ideal solution to many difficult and demanding wiring installations making a permanent and dependable wiring cable system for all low and medium voltage applications. Safe in hazardous installations and radio active environments. Exceeds all world wide fire performance standards. The Sunwin MI Cable System is the natural choice for domestic, commercial and industrial applications.

Mineral insulated cable is manufactured from completely inorganic material. The copper sheath and conductors, insulated with magnesium oxide ensure that the cable is able to withstand the effects of fire and is fully usable afterwards.

Will neither burn nor support combustion.

Our cables have a smaller diameter than soft skinned fire resistant cables of equivalent ratings.

Impervious to water, oil and gas.

Withstands considerable stresses such as bending, twisting and flattening, even in a fire situation.

Continuous operating temperature up to 250°C and for shorter periods up to 1083°C, the melting point of copper.

Mineral insulated cable is fully annealed and consequently extremely ductile and easily manipulated to follow existing wiring routes and irregular shapes.

With a non-flammable copper sheath the highly compacted insulation will resist the transmission of vapours, gases and flames between items of equipment connected by the cable.

Mineral insulated cable is permanent and does not weaken or degrade with age offering longer and safer life spans.

Our cables do not require a separate earth continuity conductor as the outer copper sheath serves this purpose providing excellent low resistance earth continuity.

·Hospital operating rooms

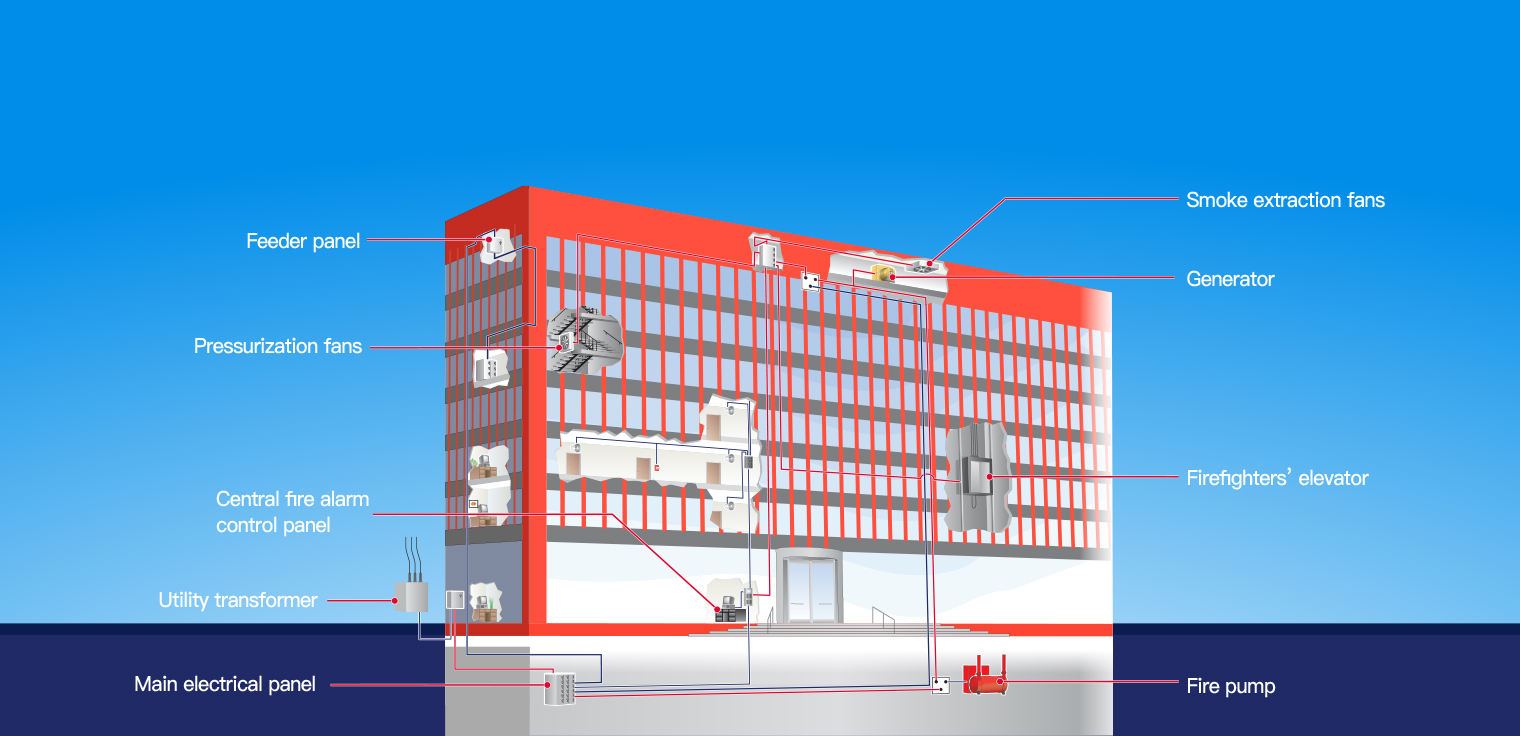

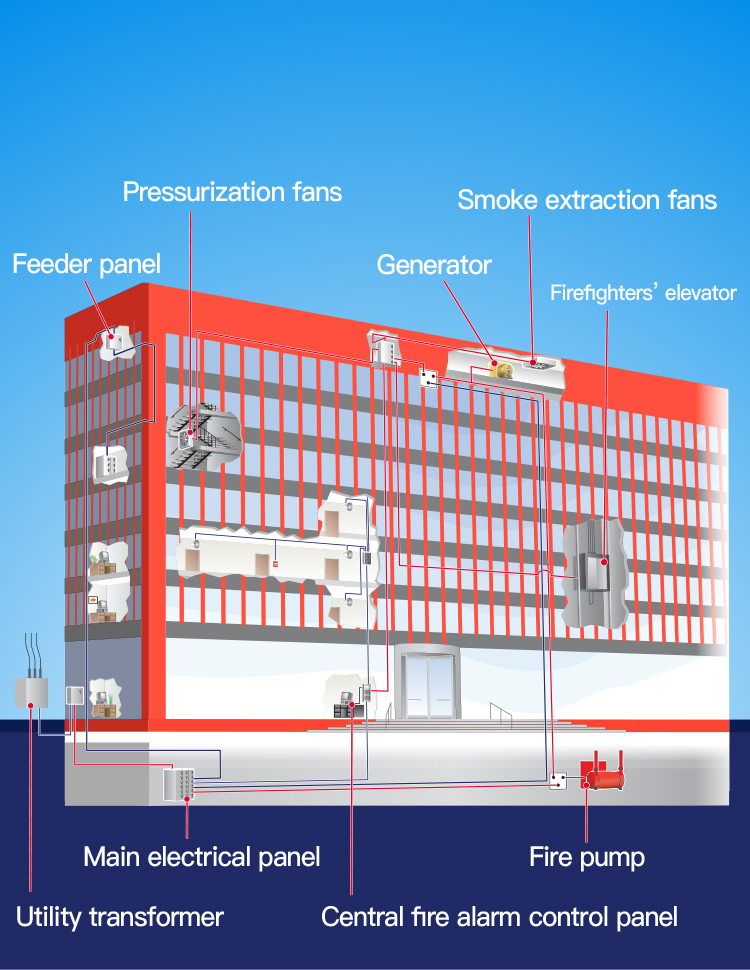

·Air pressurisation system for stairwells

·Fire alarm systems

·Emergency power systems、Emergency lighting systems

·Sprinkler systems

·Public buildings e.g. theatres, cinemas, hotels, schools

· Tunnels and mines

· Temperature measurement devices; RTD's, thermocouples

· Close to or inside industrial foundries, kilns

· Hazardous areas where flammable gases may be present

· Transport hubs - railway stations, airports etc

Fire Performance BS 6387 Performance Requirements for Cables Required to Maintain Circuit Integrity under Fire Conditions.This standard details the following tests to categorise cables according to their fire withstand capabilities.

The cable is tested by exposure to gas burner flames while passing a current at its rated voltage.

Four survival categories are defined in the Performance Table below.

A new sample of cable is exposed to flames at 650°C for 15 minutes whilst passing a current at the rated voltage and then the spray is turned on to give exposure to both fire and water for a further 15 minutes.

The grade results are as follows:

The final requirement is mechanical shock damage. A fresh sample of cable is mounted on a backing panel in an S-bend and is exposed to flames whilst the backing panel is struck with a solid steel bar the same diameter as the cable under test every 30 seconds for 15 minutes.

Whilst the cable has been exposed to temperatures as defined in the Performance Table below.

Sunwin MI Cable can easily comply and withstand the most onerous categories of C, W and Z using one single Cable Sample